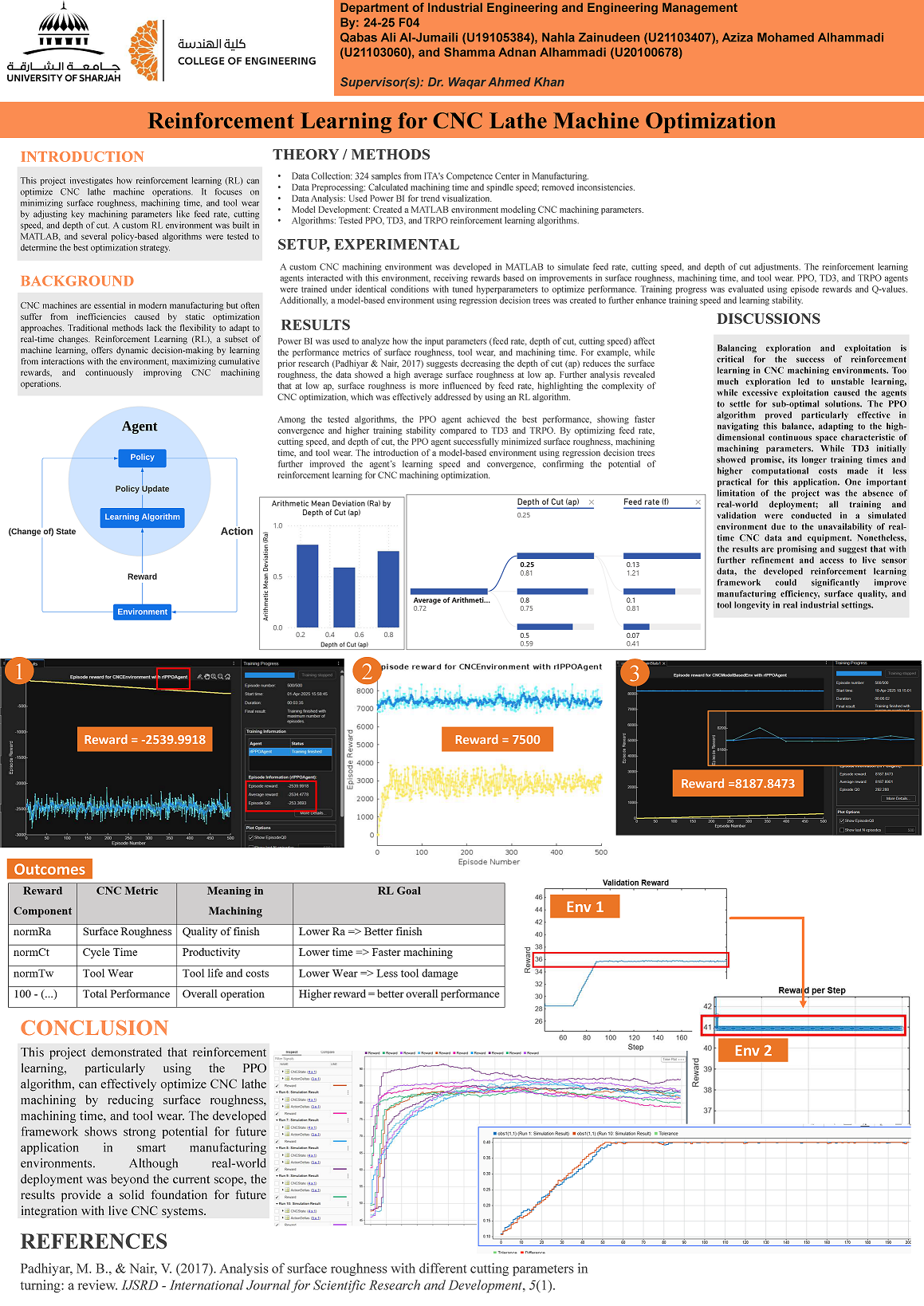

Reinforcement Learning for CNC Lathe Machine Optimization

CNC machines are essential in modern manufacturing but often suffer from inefficiencies caused by static optimization approaches Traditional methods lack the flexibility to adapt to real time changes Reinforcement Learning (RL) a subset of machine learning offers dynamic decision making by learning from interactions with the environment, maximizing cumulative rewards, and continuously improving CNC machining operations. This project investigates how RL can optimize CNC lathe machine operations It focuses on minimizing surface roughness, machining time, and tool wear by adjusting key machining parameters like feed rate, cutting speed, and depth of cut A custom RL environment was built in MATLAB, and several policy based algorithms were tested to determine the best optimization strategy.