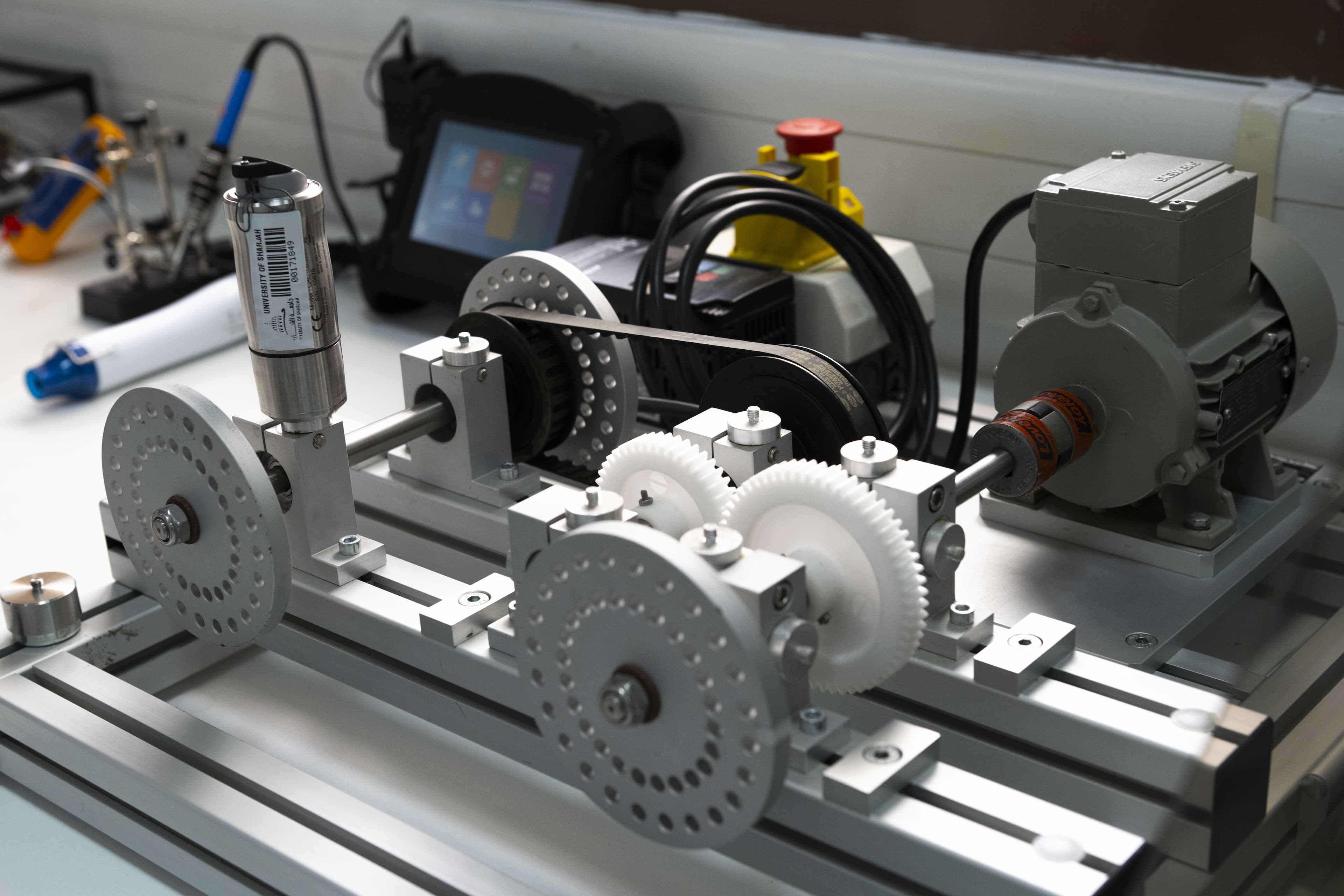

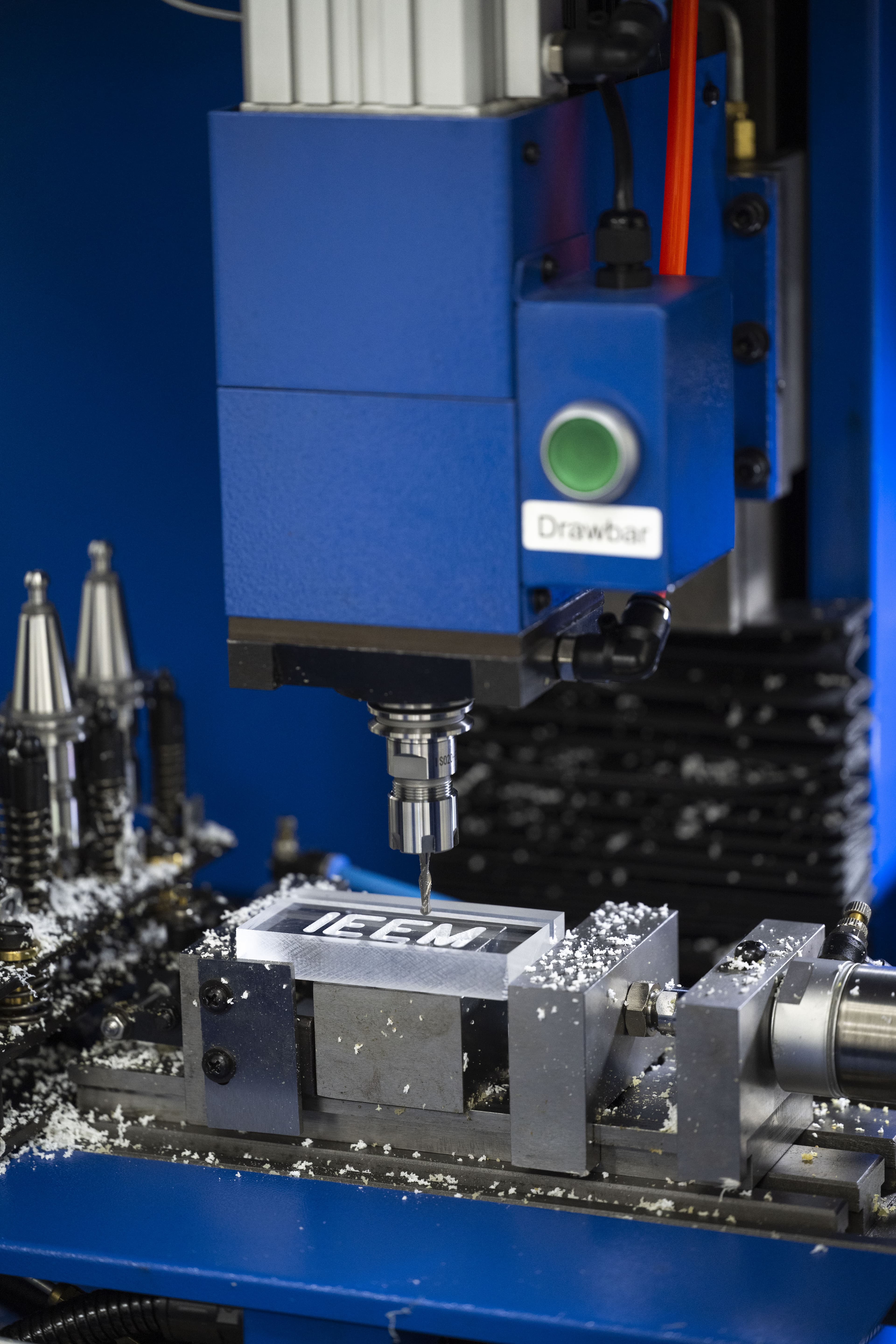

Smart Manufacturing Laboratory (IEEM Department)

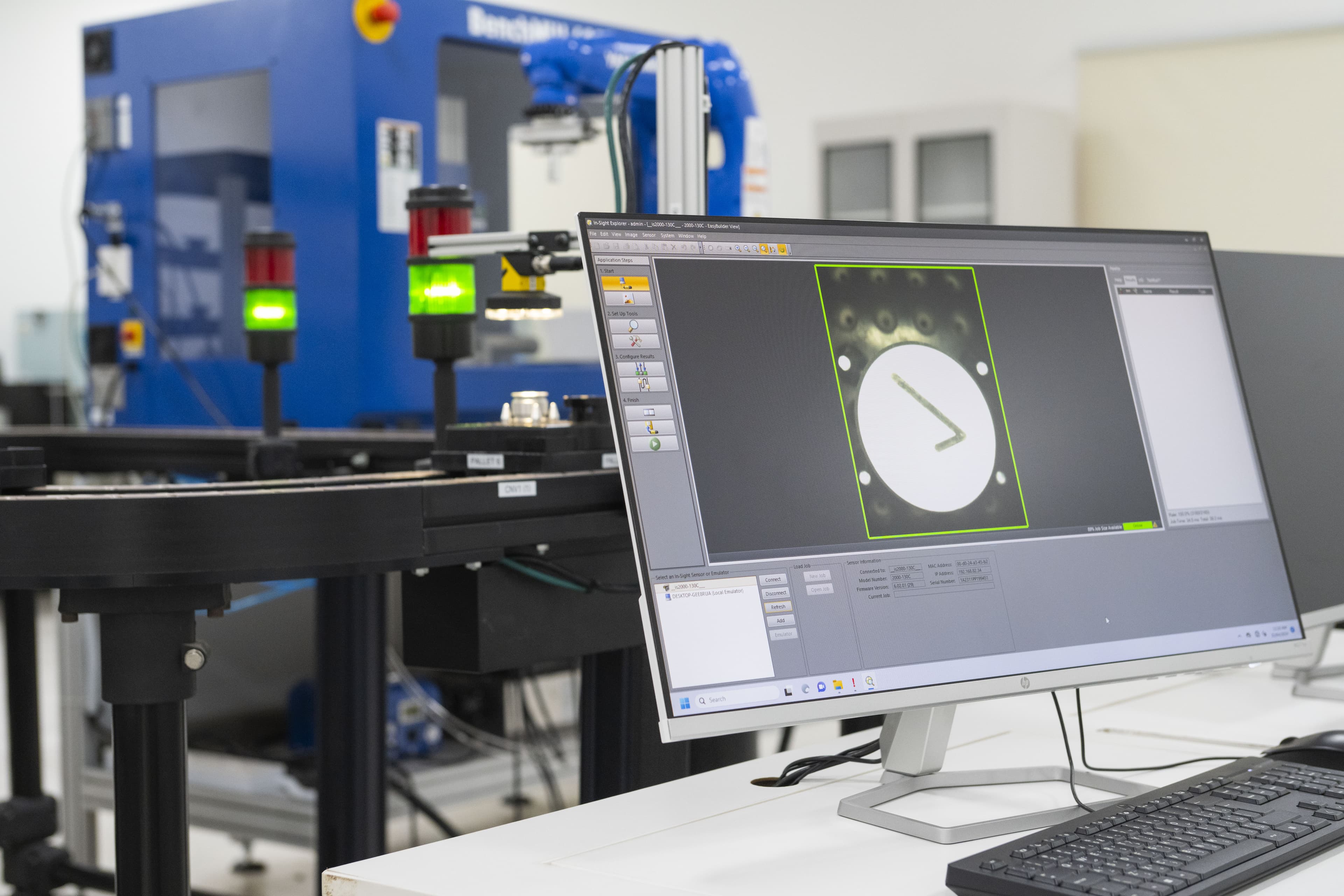

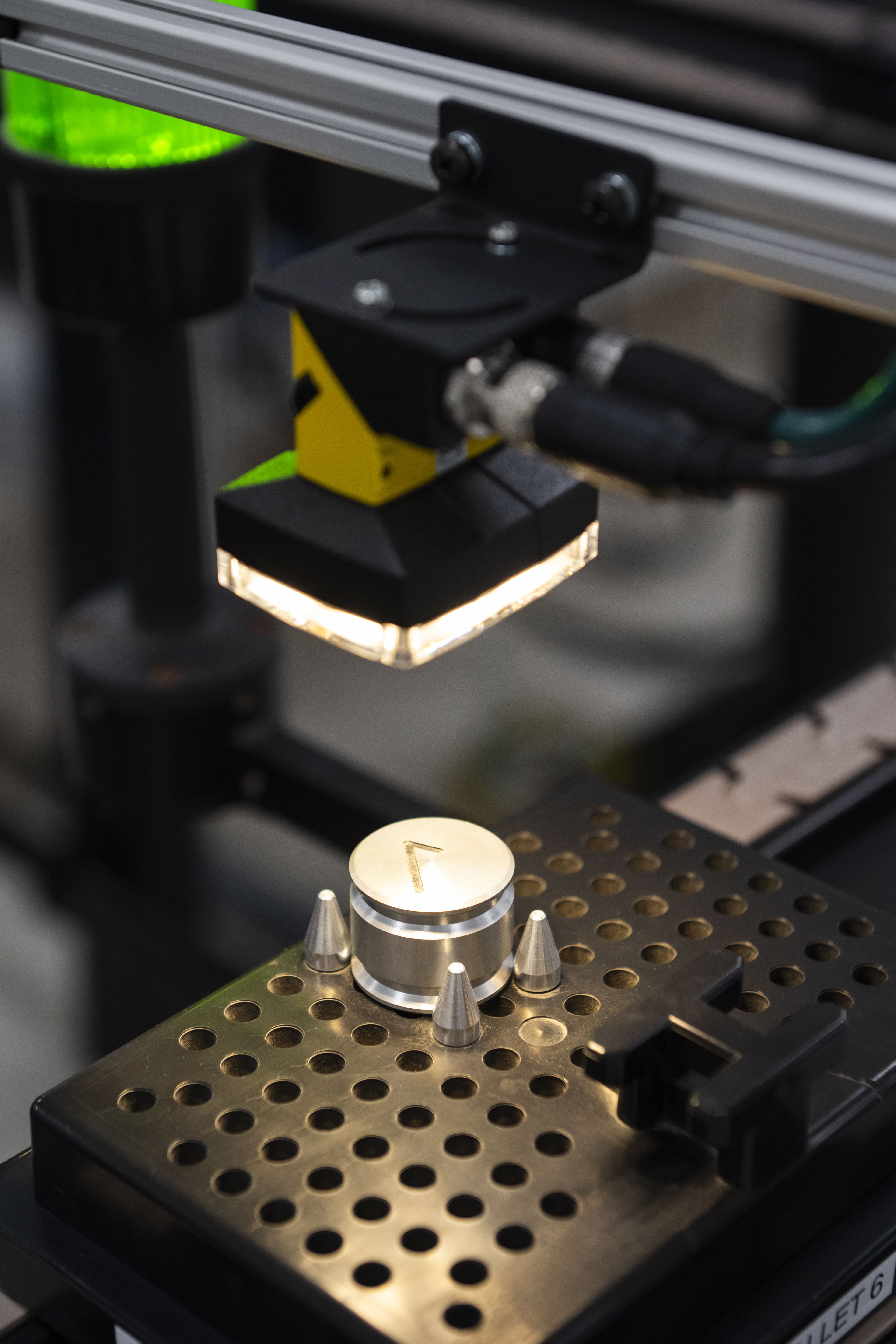

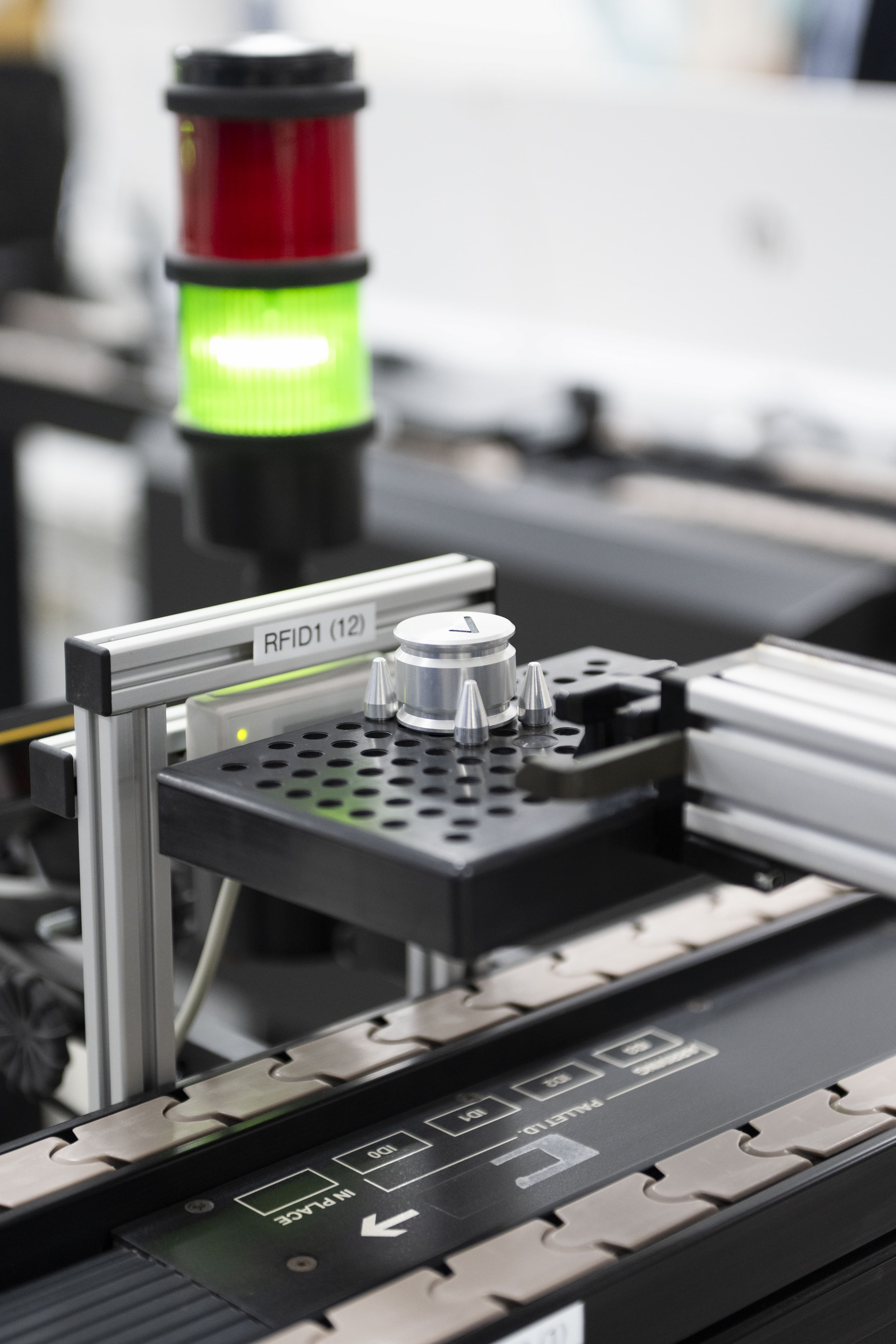

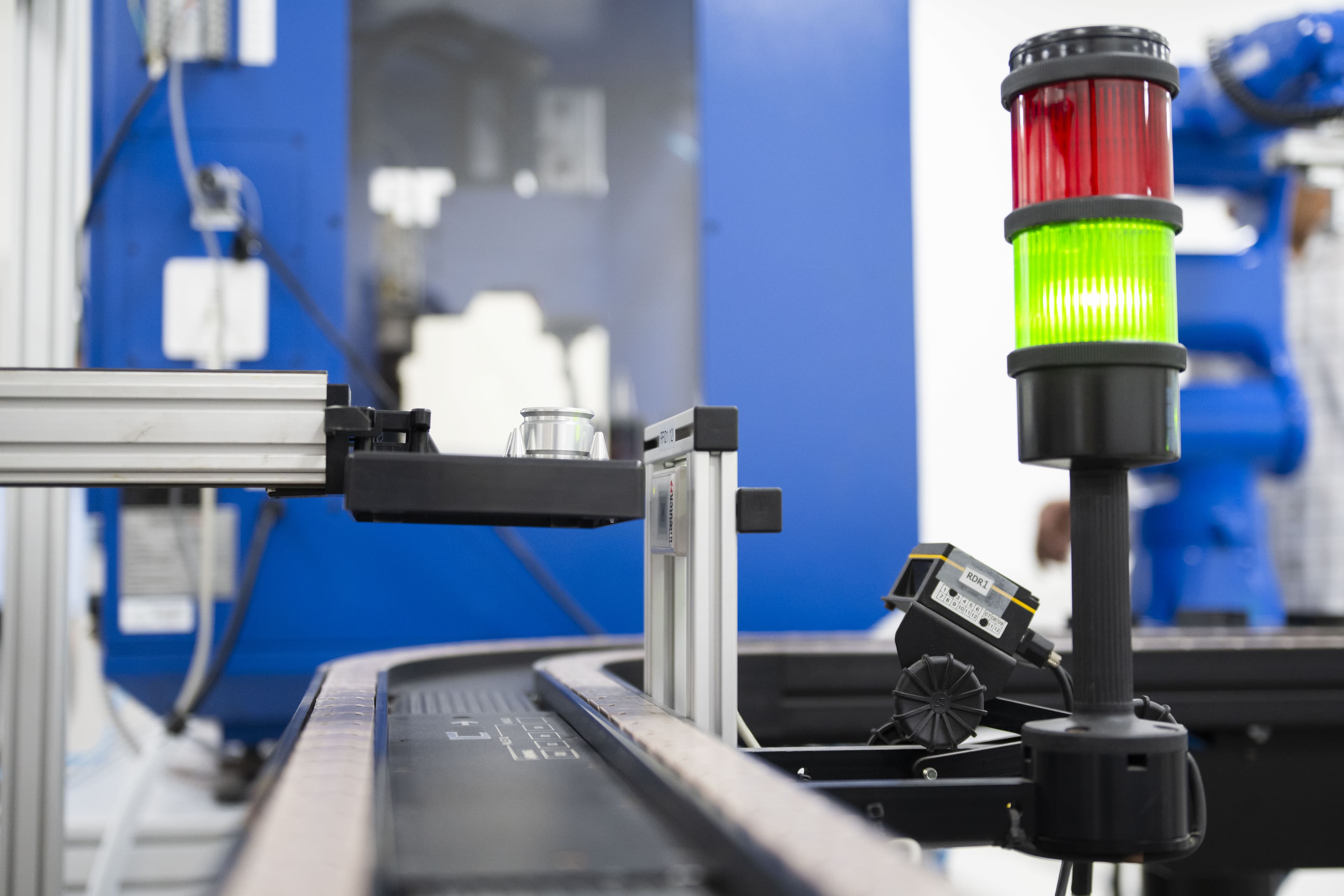

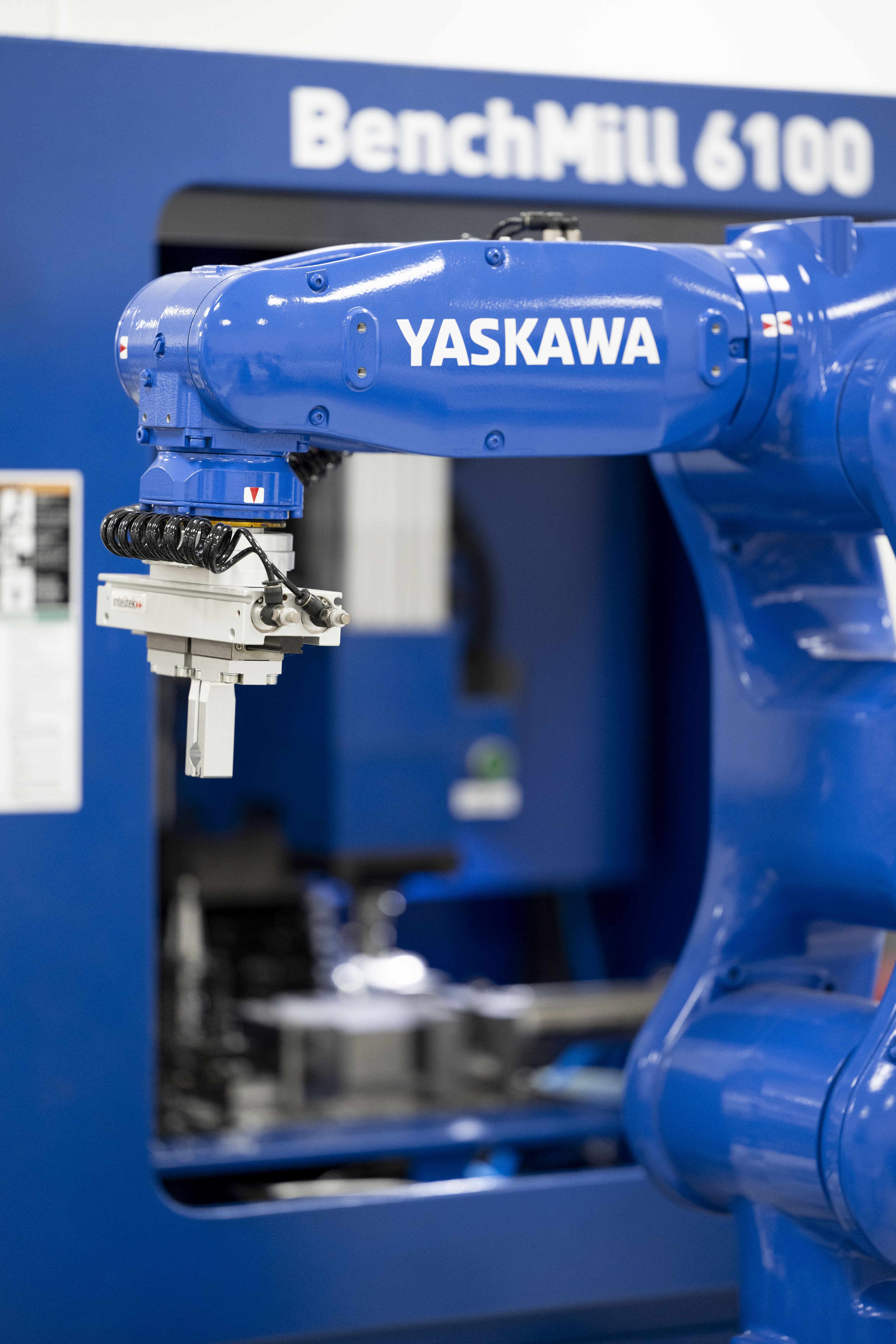

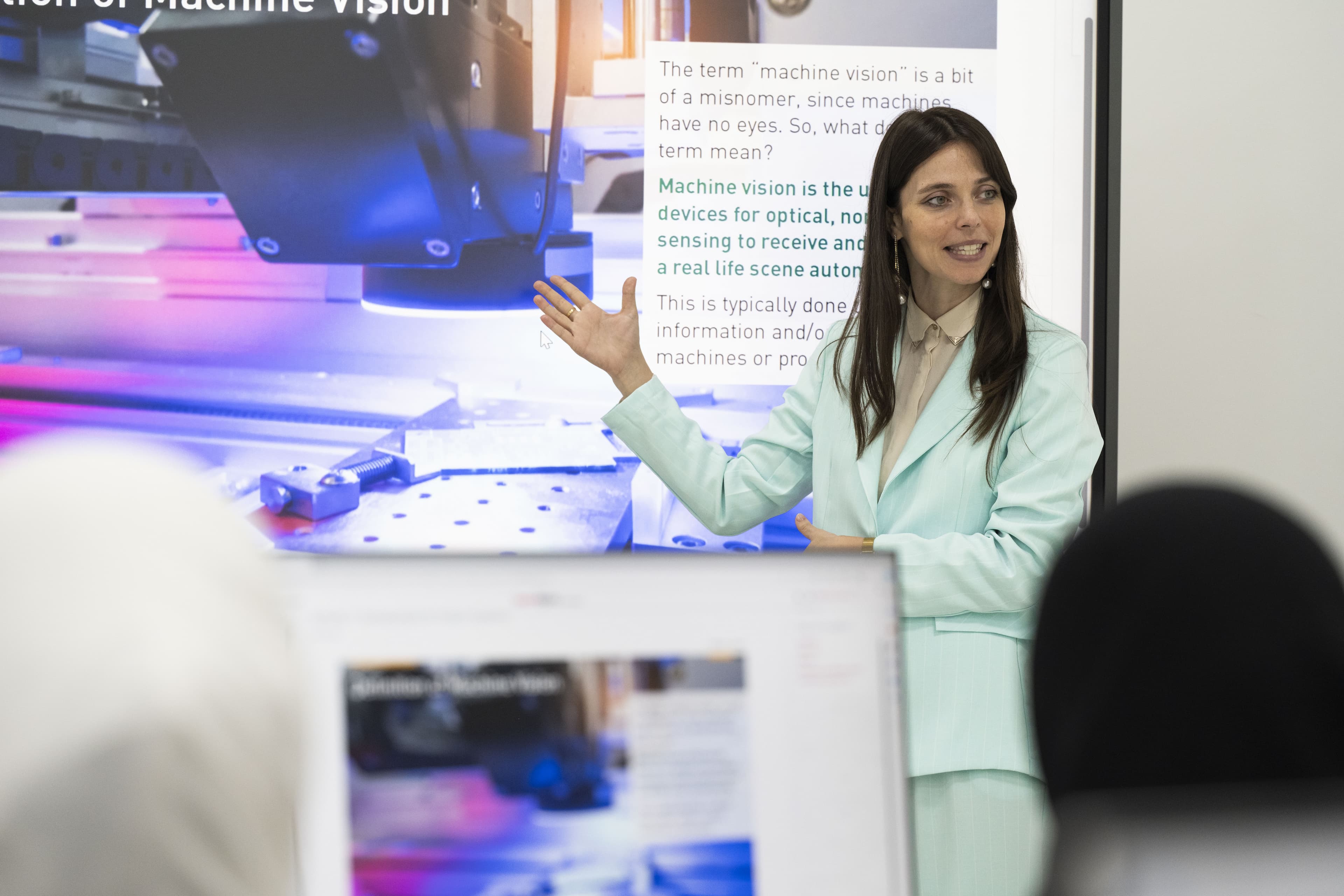

Welcome to the Smart Manufacturing Laboratory of the IEEM department! The Smart manufacturing lab aims to integrate digital technologies such as artificial intelligence, the Internet of Things, robotics, and digital twin into a manufacturing system. The lab is a structured manufacturing system that transforms raw materials or components into finished products in line with the principles of Industry 4.0. It encompasses all aspects of production in five different industrial workstations: design, planning and scheduling, material handling, machining/assembly and quality control.

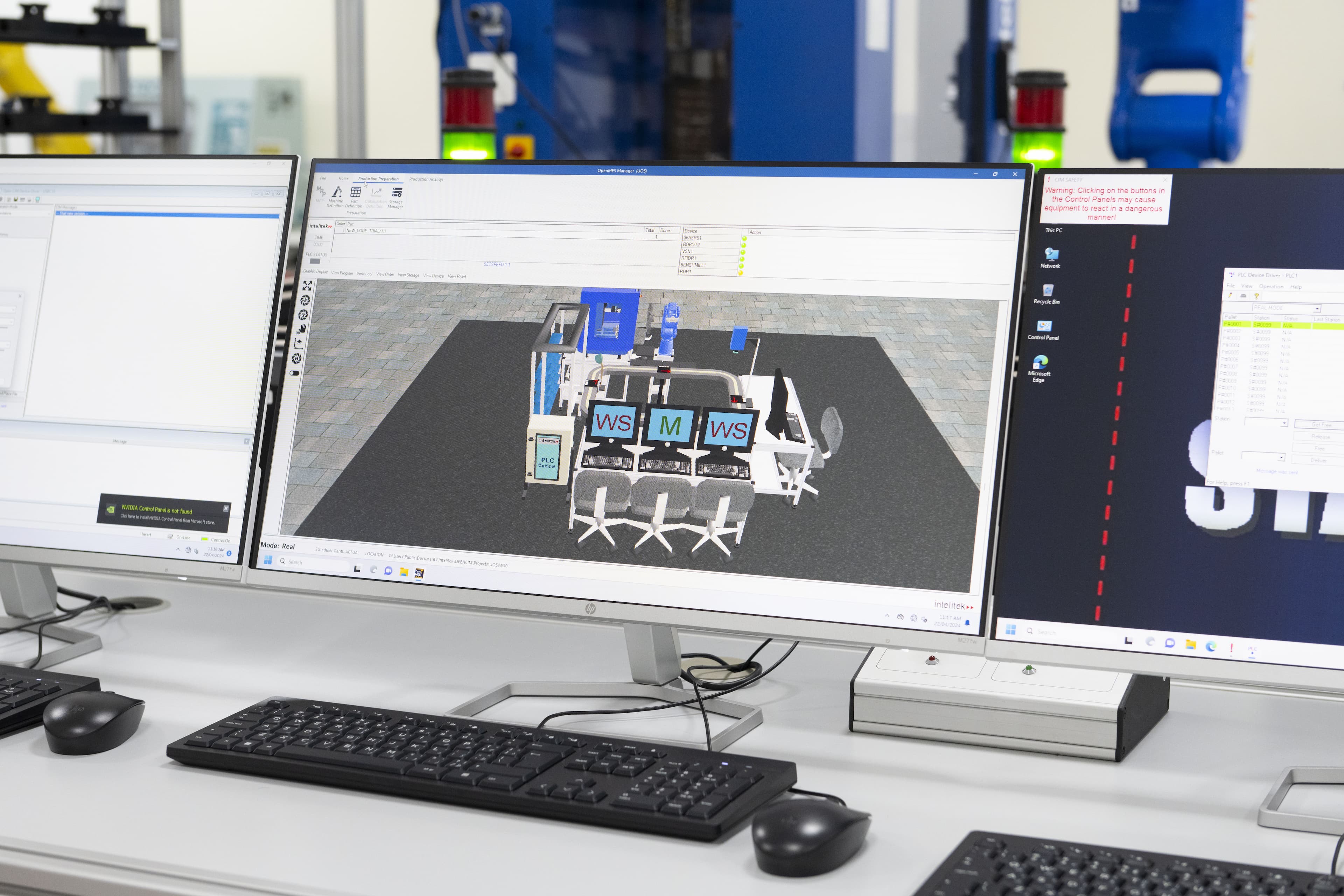

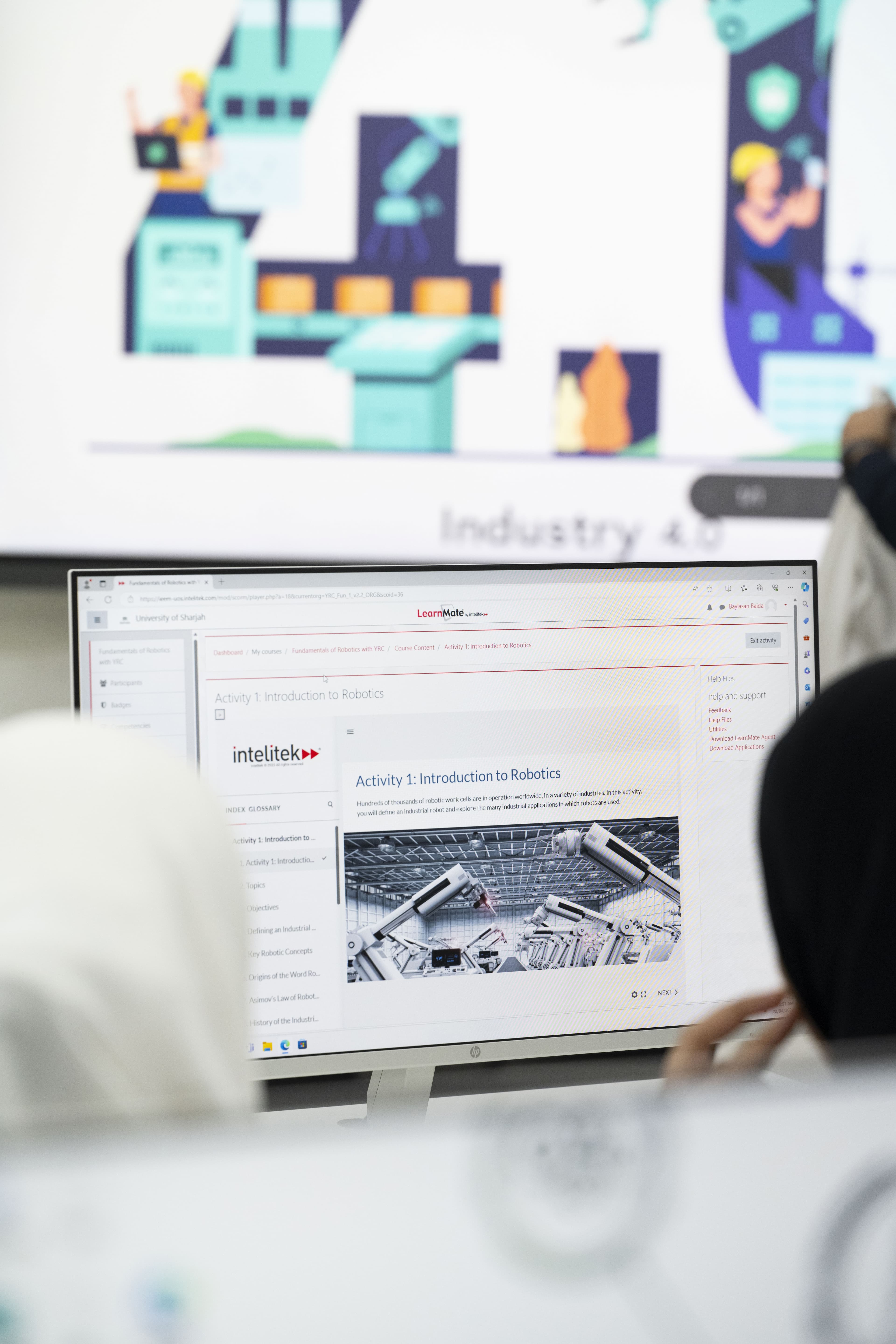

The system technologies can also be accessed through twenty different computer workstations, providing students with a controlled environment for testing and validating Industry 4.0 solutions before the actual deployment using the physical assets.